Home » Products » Welding Positioners » Welding Turntable – BTT (1AX)

BTT model Turn Table is widely used industrial, petro-chemical, chemical, energy power plant, transmission, ship building, etc.sectors

T-SE

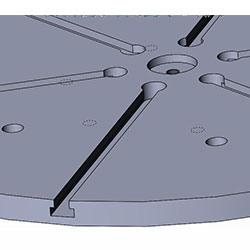

Round Worktable T-Side Entry Grooved Thick Table Plate

DFPSE

Double Foot Pedal with Stick and Stop (3m)

SFP

Single Foot Pedal (3m)

OHC

Overhead Hangable Control

WRC

Wireless Remote Control

BTT-M02

Fastening Apparatus

PLC

PLC Control System with HMI Display

We will gladly assist you in making the right decision to achieve your business goals.

Are You The Manufacturer Or A Trading Company?

BIREL ENGINEERING is the manufacturing factory which found in 2014, Bursa / Türkiye.

Can This Machine Be Customized According To My Requirements?

Yes , We have many kinds of machines for different requirements. Also can customize specially.

MODEL: BTT | Sym | Unit | BTT-1 | BTT-2 | BTT-3 | BTT-5 | BTT-10 | BTT-25 | BTT-50 |

Loading Capacity | kg | 1000 | 2000 | 3000 | 5000 | 10000 | 25000 | 50000 | |

Rotation Speed | rpm | 0.15 - 1.4 | 0.06 - 0.55 | 0.06 - 0.55 | 0.06 - 0.55 | 0.06 - 0.33 | 0.05 - 0.20 | 0.05 - 0.20 | |

Welding Current | A | Amp | 700 | 700 | 700 | 1000 | 1000 | 1000 | 1000 |

Offfset Distance | Y | mm | 150 | 150 | 150 | 130 | 100 | 80 | 80 |

Table Plate Diameter | ØD | mm | 850 | 900 | 1000 | 1250 | 1500 | 1800 | 2000 |

Diameter that can be fixed onto the aparatus | ØDmin - ØDmax | mm | 200-2000 | 200-2000 | 200-2000 | 200-2200 | 600-4400 | 600-4400 | 600-4400 |

Height | H | mm | 400 | 450 | 490 | 490 | 650 | 720 | 770 |

Length | A | mm | 860 | 980 | 1020 | 1250 | 1350 | 1550 | 1660 |

Width | A | mm | 860 | 980 | 1020 | 1250 | 1350 | 1550 | 1660 |

Power of Worktable | kW | 0.37 | 0.37 | 0.37 | 0.37 | 0.55 | 0.75 | 1.1 | |

Weight | kg | 360 | 570 | 570 | 840 | 1250 | 2100 | 3200 |

Birel Engineering has brought new solutions to Welding Equipment sector with all new designs realized by her own engineering.

COMPANY

PRODUCTS

© 2025 Birel Makina All rights reserved

Request a quote

Welding Turntable – BTT (1AX)