Home » Products » Welding Positioners » Welding Rotary Table – BHP (3AX)

BHP model Hydraulic Elevating Positioner is designed at best suitable configuration to supply function of worktable rotation & tilting of worktable angularly.

Dissimiliar to other positioners, Upon BHP model Hydraulic Elevating Positioner , Although the workpiece is mounted on the workplate, Height is adjustable hydraulically.Thus, Operators can work more effective & efficient. BHP model Hydraulic Elevating Positioner, without considering of any geometric shape , all parts within dimensions has capability of positioning & forming suitable welding edge.

BHP model Hydraulic Elevating Positioner, as structuraly are constituted of Body, Motor ,Worktable rotation and tilting systems, electric panel and cable remote operator control. BHP model Hydraulic Elevating Positioner as structuraly has the best protective system. Against heavy parts positioner should be anchored to the facility ground.

Rotation of BHP model Hydraulic Elevating Positioner’s Worktable is done by means of gear transmission system and tilting and height movements are performed by hydraulic system.

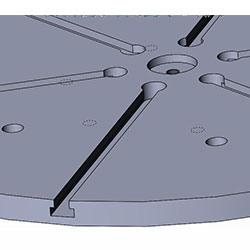

Enable quick connection of workpiece by means of Slot Groove or T-Groovedworktable. BHP-Hydraulic Elevating Positioner WorkTable is supplied as standard with Slot grooved. Optionally, If Worktable is requested as T-Grooved Thick Plate also can be manufactured as an option.

T-SE

Round Worktable T-Side Entry Grooved Thick Table Plate

OC-T

Octagonal Welding Table

BGR

3-Jaw Manual Pipe Gripper

DFPSE

Double Foot Pedal with Stick and Stop (3m)

SFP

Single Foot Pedal (3m)

OHC

Overhead Hangable Control

WRC

Wireless Remote Control

PLC

PLC Control System with HMI Display

We will gladly assist you in making the right decision to achieve your business goals.

Are You The Manufacturer Or A Trading Company?

BIREL ENGINEERING is the manufacturing factory which found in 2014, Bursa / Türkiye.

Can This Machine Be Customized According To My Requirements?

Yes , We have many kinds of machines for different requirements. Also can customize specially.

BHP | Sym | Unit | BHP-050 | BHP-075 | BHP-1 | BHP-1,5 | BHP-2 | BHP-3,5 | BHP-5 | BHP-8 | BHP-10 | BHP-15 |

Loading Capacity | kg | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 5000 | 8000 | 10000 | 15000 | |

Rotation Speed | rpm | 0.15 - 1.75 | 0.15 - 1.5 | 0.15 - 1.4 | 0.15 - 1.3 | 0.15 - 1 | 0.15 - 1 | 0.15 - 0.78 | 0,1 - 0,66 | 0,1 - 0,5 | 0,06 - 0,63 | |

Max. Rotational Torque | A | Nm | 750 | 1150 | 1570 | 2290 | 3050 | 5300 | 7500 | 12050 | 15050 | 18000 |

Tilting Angle | Y | deg | 120 | 125 | 120 | 120 | 120 | 115 | 110 | 110 | 110 | 125 |

Tilting Torque | Nm | 1350 | 2200 | 3300 | 4500 | 5600 | 11050 | 17300 | 28680 | 37050 | 76850 | |

Max. Welding Current | A | Amp | 400 | 700 | 700 | 700 | 700 | 700 | 1000 | 1000 | 1000 | 1000 |

Offfset Distance | X-Y | mm | 150-150 | 150-150 | 150-150 | 150-150 | 150-150 | 150-150 | 150-150 | 150-150 | 150-150 | 450-120 |

Work Plate Diameter | ØD | mm | 700 | 700 | 850 | 850 | 900 | 1000 | 1150 | 1250 | 1350 | 1450 |

Height (Min-Max.) | H1-H2 | mm | 710-1200 | 760-1310 | 800-1340 | 825-1450 | 910-1545 | 960-1575 | 1000-1600 | 1050-1645 | 1160-1830 | 1300-2230 |

Length | A | mm | 1900 | 1960 | 2240 | 2255 | 2375 | 2575 | 2900 | 3100 | 3200 | 3330 |

Width | B | mm | 650 | 660 | 780 | 810 | 880 | 960 | 1130 | 1300 | 1460 | 1820 |

Motor Power of Table | kW | 0,25 | 0,37 | 0,37 | 0,55 | 0,55 | 0,75 | 1,1 | 1,5 | 1,5 | 2,2 | |

Motor Power of Hydraulic Unit | kW | 0,75 | 1,1 | 1,1 | 1,5 | 1,5 | 2,2 | 2,2 | 3 | 5,5 | 5,5 | |

Weight | kg | 585 | 650 | 880 | 1300 | 1420 | 1650 | 2720 | 3500 | 4600 | 6820 |

Birel Engineering has brought new solutions to Welding Equipment sector with all new designs realized by her own engineering.

COMPANY

PRODUCTS

© 2025 Birel Makina All rights reserved

Request a quote

Welding Rotary Table – BHP (3AX)