Home » Products » Welding Rotators » Pipe Rotator For Welding – BPR

DFPSE

Double Foot Pedal with Stick and Stop (3m)

SFP

Single Foot Pedal (3m)

OHC

Overhead Hangable Control

MP

Master Panel

WRC

Wireless Remote Control

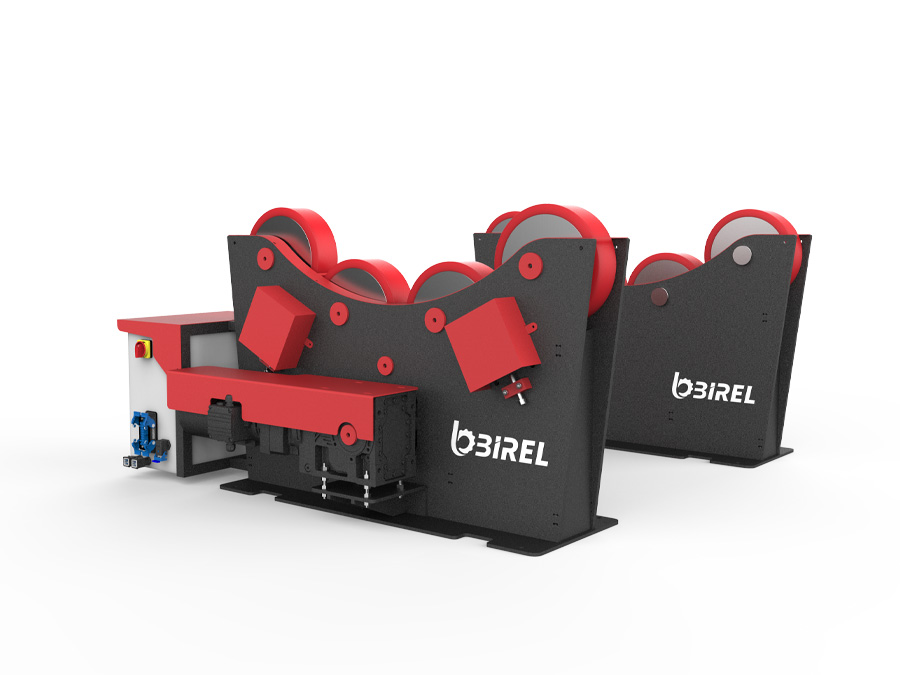

MB-BPR

Manual Buggy Adaptation

MB-BPR+T

Manual Buggy System with Table

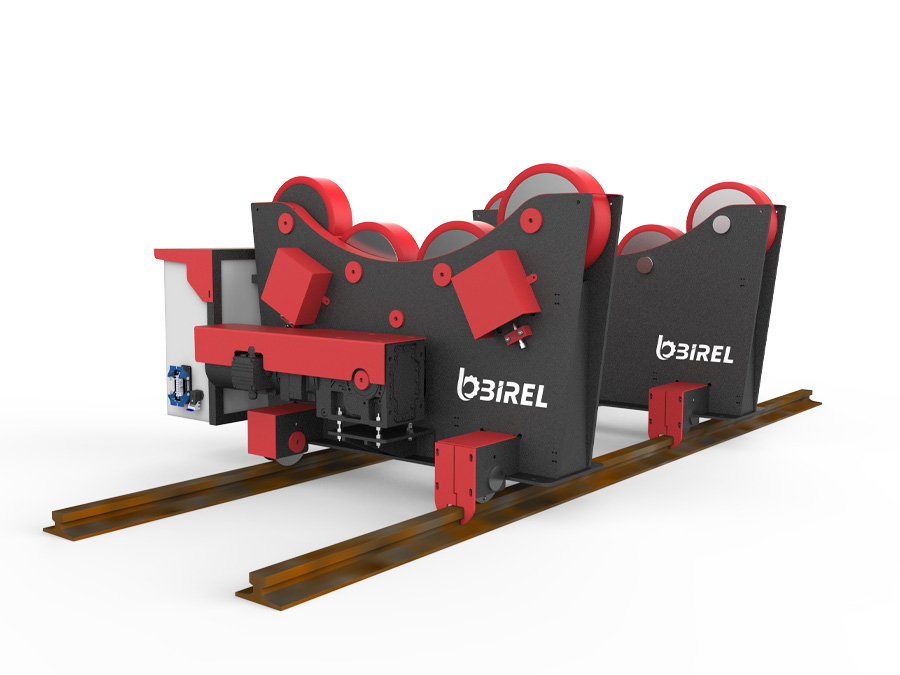

T-BPR

Rail Table

We will gladly assist you in making the right decision to achieve your business goals.

Are You The Manufacturer Or A Trading Company?

BIREL ENGINEERING is the manufacturing factory which found in 2014, Bursa / Türkiye.

Can This Machine Be Customized According To My Requirements?

Yes , We have many kinds of machines for different requirements. Also can customize specially.

BPR | Sym | Unit | BPR-3 | BPR-6 |

Capacity | ton | 3 | 6 | |

Max. Load (Drive Unit) | t/unit | 1,5 | 3 | |

Max. Load (Idler Unit) | t/unit | 1,5 | 3 | |

No. of Driwen | WD | Standart | Standart | |

Rotation Speed | mm/min | 200-1800 | 200-1550 | |

Ø Range min-max 100% load | Ødmin ØDmax | mm | 60-1420 | 90-1420 |

Wheel Diameter | ØF | mm | 200 | 270 |

Wheel Material | PU | PU | ||

Length (Drive-idler Unit) | A | mm | 1090 | 1375 |

Width (Drive Unit) | E | mm | 410 | 500 |

Width - Buggy (Drive Unit) | E-B | mm | 490 | 590 |

Width (Idler Unit) | C | mm | 220 | 340 |

Width Buggy (Idler Unit) | C-B | mm | 485 | 540 |

Height (Drive-Idler Unit) | H | mm | 510 | 750 |

Height Buggy (Drive - Idler Unit) | H-B | mm | 545 | 800 |

Buggy Rail Axis | G | mm | 620 | 660 |

External Down Chassis Width | J | mm | 790 | 920 |

External Down Chassis Length | K | mm | 3000 | 4500 |

External Down Chassis Height | L | mm | 360 | 460 |

Weight (Drive - Idler Unit) | kg | 250 | 580 | |

Weight - Buggy (Drive Idler Unit) | kg | 310 | 650 | |

Weight (External Down Chassis) | kg | 230 | 480 | |

Motor Power | kW | 0,25 | 0,37 |

Birel Engineering has brought new solutions to Welding Equipment sector with all new designs realized by her own engineering.

COMPANY

PRODUCTS

© 2025 Birel Makina All rights reserved

Request a quote

Pipe Rotator For Welding – BPR