Home » Products » Welding Rotators » Pipe Rotator For Welding – BSR

DFPSE

Double Foot Pedal with Stick and Stop (3m)

SFP

Single Foot Pedal (3m)

OHC

Overhead Hangable Control

MP

Master Panel

WRC

Wireless Remote Control

BCBS

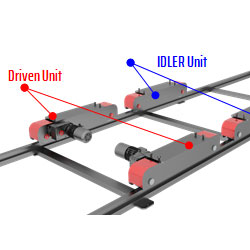

Driven + Idler Buggy Set

We will gladly assist you in making the right decision to achieve your business goals.

Are You The Manufacturer Or A Trading Company?

BIREL ENGINEERING is the manufacturing factory which found in 2014, Bursa / Türkiye.

Can This Machine Be Customized According To My Requirements?

Yes , We have many kinds of machines for different requirements. Also can customize specially.

BSR | Sym | Unit | BSR-5 | BSR-10 | BSR-15 | BSR-20 | BSR-30 | BSR-40 | BSR-50 | BSR-60 | BSR-80 | BSR-100 | BSR-120 |

Capacity | ton | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 120 | |

Max. Load (Drive Unit) | t/unit | 2.5 | 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | |

Max. Load (Idler Unit) | t/unit | 2.5 | 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | |

No. of Driwen | WD | No. | 1WD | 2WD | 2WD | 2WD | 4WD | 4WD | 4WD | 4WD | 4WD | 4WD | 4WD |

Rotation Speed | min-max | mm/min | 150-1130 | 150-1220 | 150-1230 | 150-1350 | 150-1300 | 150-1200 | 150-1230 | 150-1300 | 150-1230 | 150-1200 | 150-1230 |

Diameter Range | Ødmin ØDmax | mm | 250-3000 | 450-3000 | 450-3300 | 450-4600 | 500-4600 | 500-4600 | 500-4600 | 550-5200 | 550-5500 | 600-5500 | 600-5500 |

Wheel Diameter | ØF | mm | 240 | 340 | 340 | 375 | 415 | 440 | 440 | 500 | 550 | 550 | 550 |

Wheel Width | G | mm | 75 | 100 | 110 | 125 | 125 | 130 | 130 | 150 | 175 | 220 | 240 |

Wheel Coating | PU | PU | PU | PU | PU | PU | PU | PU | PU | PU | PU | ||

Length (Drive Unit) | A | mm | 1540 | 2580 | 2400 | 2480 | 2680 | 2700 | 2830 | 3000 | 3200 | 3260 | 3380 |

Length (Idler Unit) | B | mm | 1140 | 1970 | 1970 | 2020 | 2150 | 2330 | 2330 | 2740 | 2860 | 2880 | 2880 |

Width (Drive Unit) | E | mm | 840 | 720 | 900 | 985 | 1050 | 1150 | 1150 | 1200 | 1280 | 1500 | 1630 |

Width (Idler Unit) | C | mm | 350 | 500 | 520 | 560 | 580 | 700 | 700 | 700 | 700 | 900 | 900 |

Height | H | mm | 517 | 880 | 880 | 940 | 1000 | 1040 | 1040 | 1260 | 1320 | 1330 | 1330 |

Motor Power | P | kW | 0,37 x 1 | 0,25 x 2 | 0,55 x 2 | 0,55 x 2 | 0,55 x 2 | 0,55 x 2 | 0,55 x 2 | 0,75 x 2 | 0,75 x 2 | 1,1 x 2 | 1,5 x 2 |

Weight | W | kg | 380 | 1100 | 1180 | 1360 | 1830 | 2540 | 2600 | 3760 | 5320 | 6200 | 6400 |

Birel Engineering has brought new solutions to Welding Equipment sector with all new designs realized by her own engineering.

COMPANY

PRODUCTS

© 2025 Birel Makina All rights reserved

Request a quote

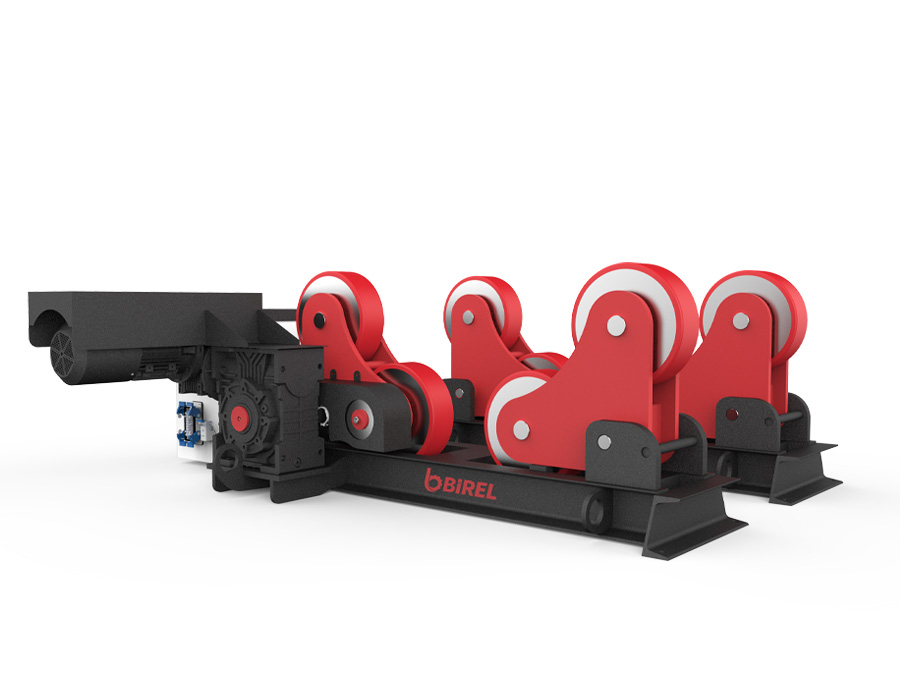

Pipe Rotator For Welding – BSR